DSM – 3D dip and saddle measurement innovation

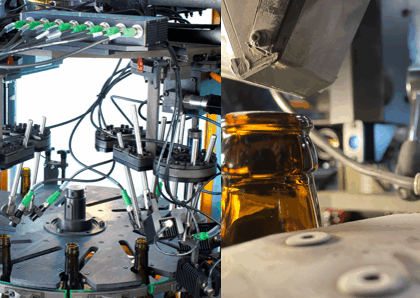

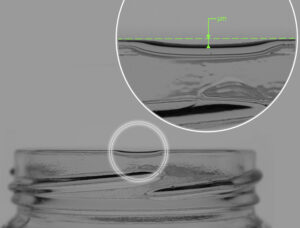

Dip and saddle measurement inspection, DSM, is an optical device that performs a 3D mapping of the container ring surface. The equipment is capable of mapping all round article finish surfaces and is effective for jars up to 110mm diameters.

[…]

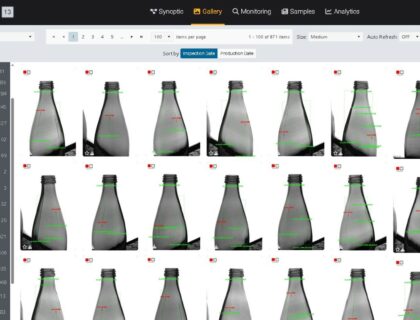

With the DSM, the Multi4 is now capable to inspect on-line all types of container finish for dip, saddle, ovalisation and off-level with such precision and repeatability that it eliminates false rejects. This way, no choice has to be made between quality and productivity.

This is an extract from a press release, if you want to read the entire article, click here.