Tiama HOT Lab: Developments of Tiama’s Hot End sampling solutions

![]()

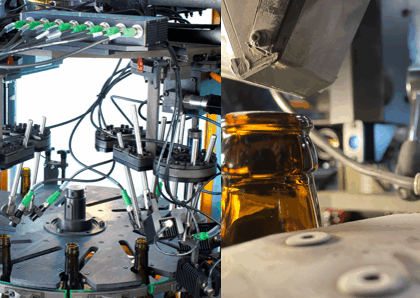

Tiama has continued to develop its range of Hot End monitoring solutions called the Tiama HOT Systems, providing key information on the HOT End process from the gob through to the fully formed container. In 2016, Tiama decided to launch a sampling solution as part of this range called the Tiama HOT lab. There are currently 30 Tiama Hot lab machines installed worldwide at key glass container producers, covering 5 different continents.

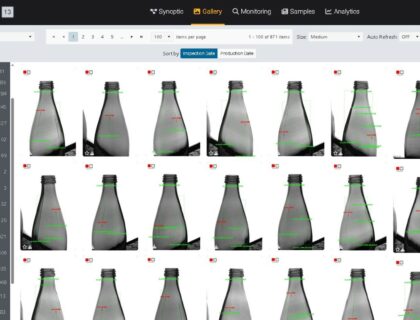

The Tiama HOT lab is an automatic statistical solution providing quick, accurate, non-contact dimensional measurements of hot bottles. These measurements include glass thickness, internal bore, tuck-under angle (D-angle) sunk & bulge and all other external diameters.

Multi-Product production

The unique design of the Tiama Hot lab ensures it provides accurate measurement solutions for the industry’s wide range of glass container designs including non-round shapes. A new feature, added at the beginning of 2020, provides a solution for measuring Multi-Product production.

Multi-Product allows the user to place an assortment of bottles, varying in height, shape and diameter into the loading cart. The robot then finds, collects and places the bottles into the Tiama HOT lab one by one and measures them all.

This is an extract of an article published in a magazine. To read the entire article click here.

If you want to know more about the Tiama HOT systems:

Here is an article about the Tiama HOT systems

Here is an article about the Tiama HOT eye

Here is an article about the Tiama HOT form

And if you have any questions, don’t hesitate to contact us at: marketing@tiama.com