Introducing the Tiama HOT blank

Tiama is proud to introduce the Tiama HOT blank, an advanced monitoring and regulation system designed to support glass manufacturers in optimizing production. It provides precise, reliable data and closed-loop to control the blank molds and plungers temperatures, ensuring enhanced efficiency and consistency. As part of the Tiama HOT systems range and aligned with the YOUniverse concept, this innovative solution provides precise and repeatable data on blank molds and plungers temperatures to enhance process stability and product quality.

Accurate and Repeatable Temperature Measurements

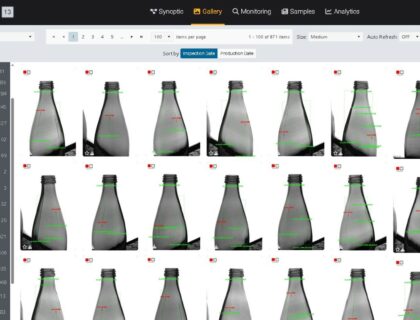

The Tiama HOT blank is equipped with a dedicated camera for each section of the IS machine. This allows the system to measure the temperature of blank molds and plungers with precision and reliability. With up to three readings per half mould and one per plunger, the system delivers up to 14 temperature points per section for a double gob IS machines.

Temperature data is recorded at every cycle and displayed on the intuitive Tiama HOT blank interface. This information can also be easily extracted for further analysis, through our Tiama ECO-system solution, helping manufacturers make informed decisions to optimize their processes.

Automatic Regulation for Enhanced Efficiency

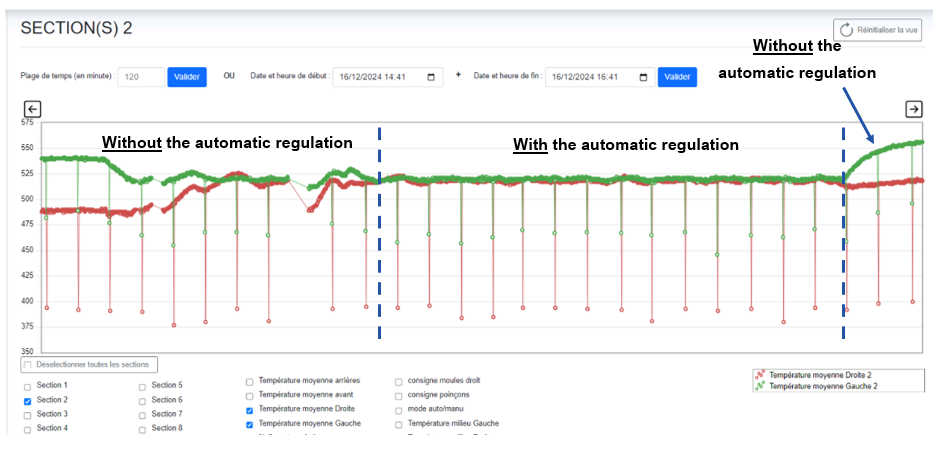

The Tiama HOT blank employs closed-loop to automatically regulate mold temperatures. By capturing precise data at every cycle, the system ensures consistent temperature management during day/night variations or seasonal changes.

The system maintains temperature stability within ±5°C of the setpoint and adjusts cooling times within predefined ranges, using the available cooling capacity efficiently. By managing electrical signals from IS machine cooling valves, the system operates universally, independent of IS machine software and electronics.

Key Benefits for Glassmakers

The Tiama HOT blank offers several practical advantages:

- Reliable and accurate temperatures measurements for all sections at each cycle

- Enhanced temperature stability, leading to fewer thermal defects and higher product quality

- Historical data trends that provide insights for process optimization and troubleshooting

- Faster identification of air-cooling issues on the IS machine, reducing downtime and improving response times.

Robust Design and Ease of Use

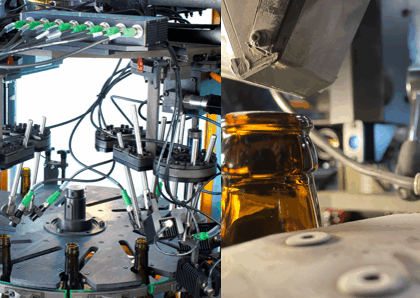

Built for durability, the system’s cameras are designed to operate in challenging environments with minimal maintenance. The compact design integrates smoothly with IS machines, and installation requires only standard factory air and water supplies (optional).

A Practical Addition to Production

The Tiama HOT blank equips glassmakers with essential data to better manage blank molds and plungers temperatures, enhancing overall production efficiency and process optimization. Its user-friendly interface makes it easy to analyze trends and identify areas for improvement, helping manufacturers achieve consistent results with confidence.

As a new and evolving solution, the Tiama HOT blank system is continuously improved through valuable customer feedback. In addition, several major new features are currently in development to further strengthen the system, providing even more comprehensive data on the blank side, such as gob loading and advanced safety monitoring.

While no system can solve every challenge, the Tiama HOT blank is designed to provide practical tools and reliable data to support better decision-making and overall process management.

The system is now available for purchase. For more information about the Tiama HOT blank, please reach out to us at marketing@tiama.com.