Improved quality of your containers through enhanced gob control with Tiama HOT mass 2

“80% of the defects created come from the gob.”

This is what glassmakers usually say about the glass process.

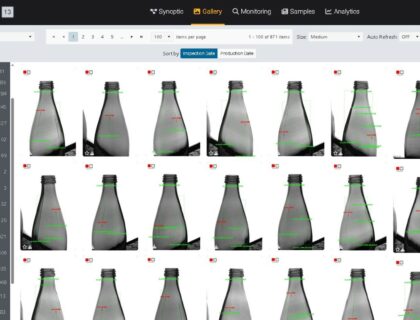

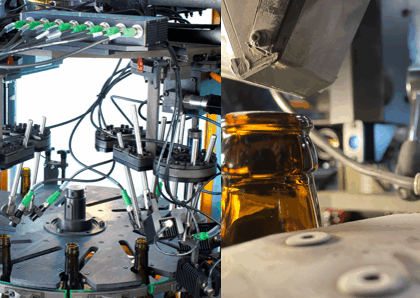

The control of the gob is one of the first steps in achieving stability of its process and thus reducing defect creation. Having a stable weight and a repeating gob shape are in particular 2 key parameters of the gob to be controlled. Today the Tiama HOT mass 2 has become a “must have” for many glass plants. Thanks to its unique configuration, the system is able to automatically regulate the gob weight via 2 closed loop: with the tube and the needles. The accuracy of the weight regulation obtained with the system is less than +/-0.25%.

As in the example below, on a Blow-Blow production with a setpoint at 955g, the Tiama HOT mass 2 is capable of automatically controlling at +/1 gram over several days, i.e. regulation at approximately +/-0.15%. This weight stabilization then makes it possible to envisage a reduction in the setpoint and thus save on glass consumption. Weight stabilization also reduces the creation of certain types of defects, such as overpress or unfilled finish, but also improves the glass distribution. In addition, the automatic gob weight control frees up time for operators who can concentrate on more added-value tasks around the IS machine. The automatic weight control is a major feature of Tiama HOT mass 2, especially for Blow-Blow or Press-Blow processes.

Please contact us if you would like more information about the system.