HOT Systems by Tiama signal greatly improved glass production

TIAMA continues to wow customers with its glass production revolution in innovative hot-end to cold-end process monitoring. Enhancing efficiency while reducing defects -all within the YOUniverse concept- the company’s technologies are leading to both significant savings and improved production quality.

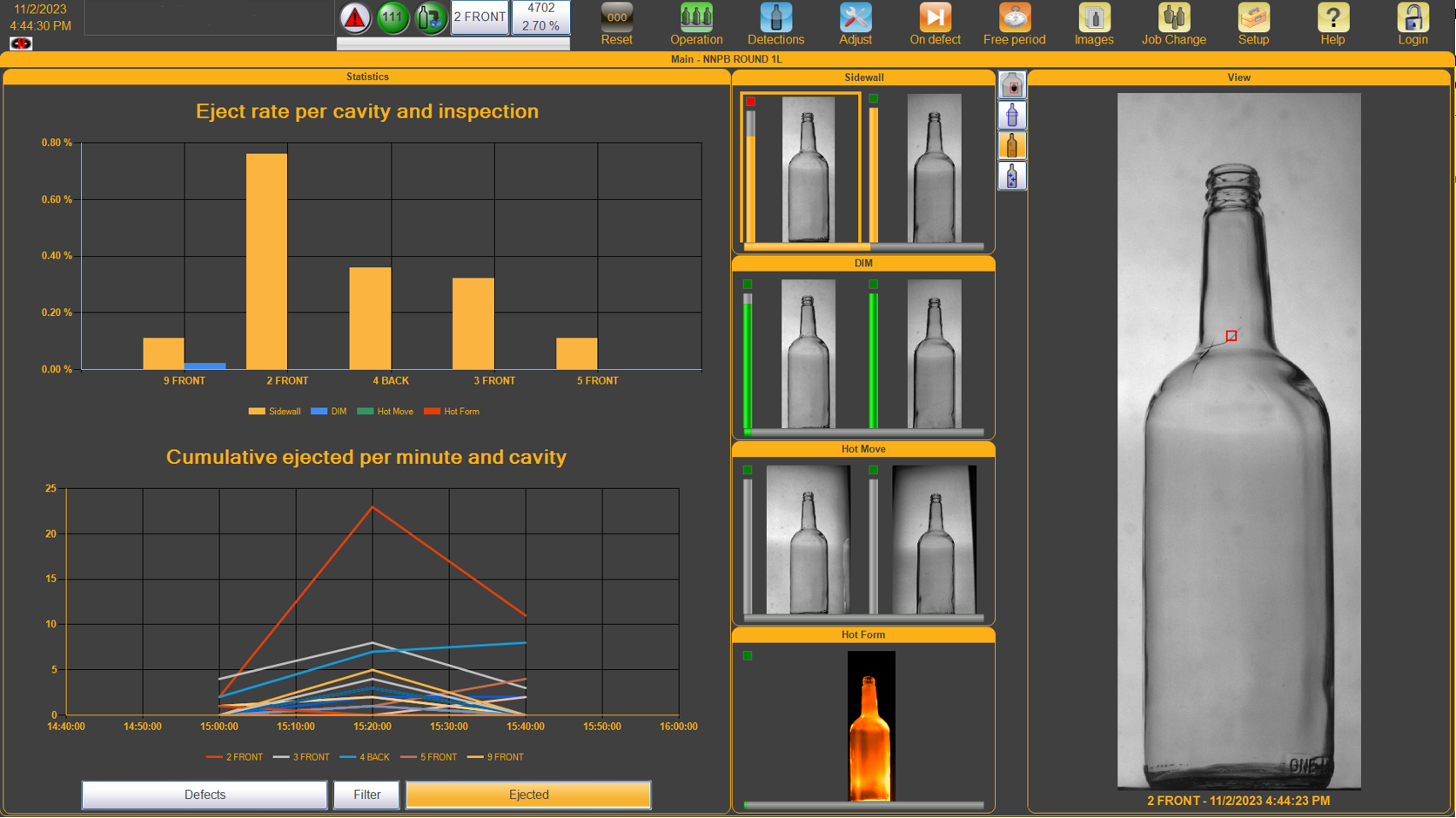

For more than ten years now, Tiama has been a major player at the hot-end launching several systems dedicated to process monitoring. The very first one was the I-Care machine which was equipped with two infrared cameras located just after the IS machine. In 2014, the company launched its HOT systems, adding to its historically-provided cold-end products a fresh range of sensors dedicated to the hot-end. This was the beginning of a new era and the first steps towards what is now known as YOUniverse. Today, the Tiama HOT systems range consists of four sensors, each located in a different area around the IS machine – from the gob with the Tiama HOT mass 2 to the exit of the IS machine with the Tiama HOT eye, the Tiama HOT form and the Tiama HOT move.

This is an abstract of an article published in Glass International. You can read the full article here on their website or download the PDF here.